Noise and vibration

(Managed by Prof. David Thompson)

Introduction

Almost all noise and vibration phenomena are affected or controlled by the design of track, but knowledge of the role of the sleeper and ballast in noise and of the track system and sub-base in vibration needs to be improved. Integrating quantitative knowledge of how the track affects and controls noise and vibration is an essential aspect of improving system performance (WA5) and environmental costing (WA6).

Wheel-rail interaction gives rise to vibration of the track across a wide frequency range. From ~4 to 80 Hz, it is transmitted through the ground and perceived in track-side buildings as ‘whole body’ vibration. The highest levels are usually from freight trains, but a special concern for the design of high speed lines is the possibility of direct excitation of the ground by high speed trains. This resulted in special and costly track/support structure design on HS1. At higher frequencies (~30 to 200 Hz), vibration gives rise to structure-borne noise in buildings from tunnels but increasingly also from at-grade lines. Airborne rolling noise (~50 Hz to 5 kHz) is the most important component of noise from moving railway vehicles up to about 300 km/hr, with the contribution from the track being usually the most significant. Rolling noise is often exacerbated at elevated structures by vibration transmitted through the ballast; this was the subject of a major design study for the Thameslink project.

All parts of the Programme addressing the sleeper, ballast and sub-base have implications for environmental noise and vibration. The dynamic stiffnesses of the ballast (WA2) and sub-base (WA1) are poorly characterised parameters in the modelling of noise, while the effective rail support stiffness (WA5) is important in noise generation. The sleeper type and material (wood, concrete, steel, plastic) also have an important effect (WA2). The dynamic transfer stiffness of the ballast layer (i.e. the stiffness between the sleeper and a substructure in the frequency range up to about 1 kHz) determines the vibration levels transmitted to ground, tunnels or bridges, and is of direct relevance in WAs 4 and 5.

Low frequency ground vibration is dominated by the dynamic stiffness of the sub-base and embankments (WA1)45. Ground vibration also depends on the vertical profile of the track top. It will be necessary to link the vibration studies to how this deteriorates over time (due, for example, to the effects that will be investigated in WAs 1, 2, 4 and 5) for different ballast layers and sub-bases. The variation of the dynamic support stiffness under sleepers (WAs 1, 2 and 5) as an additional mechanism of vibration excitation will also be investigated.

The principal excitation mechanism of rolling noise is surface unevenness (“roughness”) of the rail and wheel. Measurements undertaken in the 1990s indicated that UK rail roughness was relatively high. An extensive programme of grinding was undertaken subsequently, aimed at reducing rolling contact fatigue. The effect of this grinding on current roughness levels and how these levels are related to the track structure are unknown.

Initial objectives

- To measure the dynamic stiffness of track structure layers including the ballast in new, glued, softly-reinforced and other conditions; also the effects of sleeper pads, ballast mats and rail pads

- To assess the implications of different sleeper/ballast/sub-base combinations on noise and higher frequency vibration using appropriate numerical models

- To study variation in track support stiffness as a mechanism for vibration generation, in comparison with the known mechanisms of dynamic excitation by moving loads

- To assess the effects of the sleeper/ballast layer, other track designs and sub-base variations on low frequency vibration generation and propagation.

Additional objectives

During the project, the following additional objectives were agreed:

- To quantify wheel and rail roughness and track decay rates typical of UK track and compares with historic levels in the UK and typical levels in other countries.

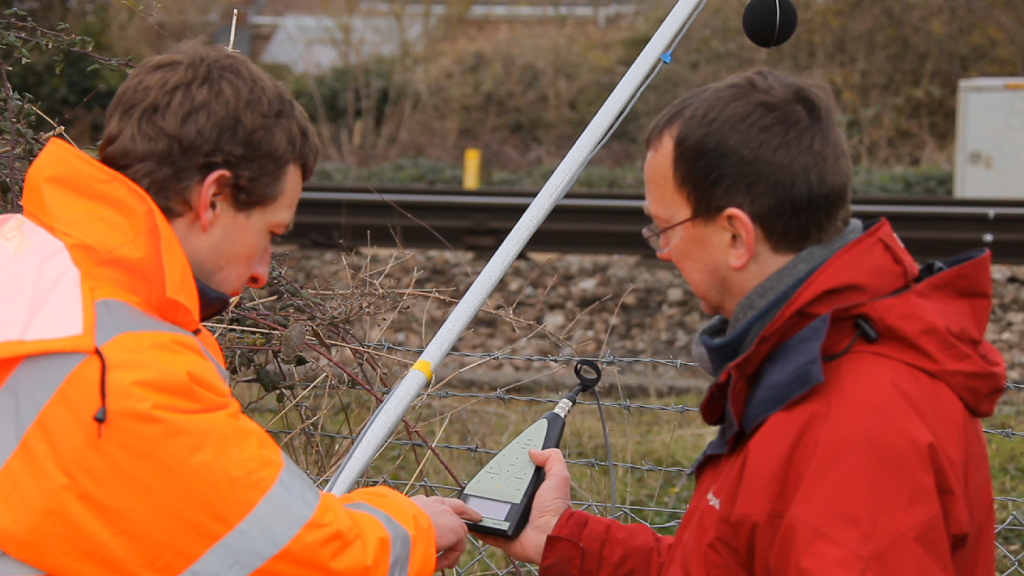

- To make field measurements of noise and vibration for different track structures and traffic in order to validate and improve prediction models.

- To develop time domain FE vehicle/track models to study critical velocity and distribution of loads through the track.

Methods

Ballast layer dynamic stiffness will be investigated in a purpose-built full scale laboratory rig, capable of measuring both the direct stiffness at the sleeper soffit and the transfer stiffness between a sleeper and a bridge deck/formation for frequencies up to about 1 kHz. The rig will be designed to measure stiffness under different loads, across the frequency range. It will also allow the introduction of ‘soft’ ballast improvements including gluing and random fibre reinforcements, sleeper pads and ballast mats. It will be used to measure the stiffness of new and aged ballast and to study the effects of grading etc. An input force impulse from an instrument hammer will be applied to a specially designed half-sleeper, and the response of the half-sleeper and a seismic mass at the base of the ballast layer measured. It will be possible to measure the dynamic material characteristics of other track and sub-base configurations using the same apparatus. The measurements will relate closely to elements of WA5, and the results will be of direct use in the evaluation of impact loads in critical zones of track in WA4.

Numerical models developed at Southampton will be used to analyse the effects on noise and vibrations of the modifications to the sleeper, ballast and track system proposed in WAs 2 and 5 in a variety of subbase and train loading conditions. In particular, the TWINS model, which has been used internationally in wheel and track component design, will be used to investigate numerically the factors influencing the level of rolling noise generated from trains. This model calculates the vibration of the wheel, rail and sleeper. The rate of attenuation of vibration along the track depends on the rail support conditions and controls the noise radiated from both the rail and the sleeper. The sleeper is modelled as a beam on a support whose stiffness represents the ballast and sub-base. Slab track can also be modelled. The effects of different sleeper materials and ballast-sleeper contact conditions will be studied using the measured dynamic stiffnesses obtained from testing different sleepers and ballast conditions in conjunction with WA2. Tests on different sleeper types and materials may also be carried out in situ using the Southampton test track.

Wavenumber finite element and boundary element (WFEBE) methods will be used for the analysis of vibration propagation, to investigate numerically the effects of changes to the materials in the track, embankment and sub-base. Conventional finite element methods are inefficient in this application, owing to the need to model a large domain to prevent wave reflection at false boundaries. In the WFEBE approach, finite elements are used to model the inhomogeneous mechanical properties and geometry of the track, ballast and formation while boundary elements are used to model the ground, achieving an infinite medium for wave propagation. Wavenumber elements assume invariance of the geometry and material properties in the along-track direction. The cross-section is modelled using a 2D mesh but the 3D vibration response to forces is obtained.

A model currently being developed within RRUK (EP/D080207) will be used to investigate the effect on vibration generation of variations in track support stiffness along the track. The model is based on a finite element approach, with interpolation along the rail to allow efficient time stepping and special elements based on dynamic flexibility matrices to model the effect of layered ground on neighbouring sleeper supports and to calculate response away from the track where necessary.

Key outputs, impacts and inputs to other Work Areas

- improved knowledge of model parameters for track dynamics, bridge noise and ground-borne noise and vibration (input to WA4)

- improved knowledge of how sub-base and track support factors and parameters affect ground vibration generation and propagation

- predictions of the effects on noise and vibration of different ballasted track system interventions (for use in WA6 for noise cost analysis); guidance on noise and vibration mitigation

- potentially, an assessment of the noise and vibration performance of more highly engineered track forms over their lifetime and in comparison with ballasted track.